Peelable Solder Mask

Price 550 INR/ Bottle

Peelable Solder Mask Specification

- Weight

- 150 Grams (g)

- Color

- white

- Product Type

- solder mask

Peelable Solder Mask Trade Information

- Payment Terms

- Cash on Delivery (COD) Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque Cash Advance (CA)

- Supply Ability

- 100 Per Week

- Delivery Time

- 1 Days

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

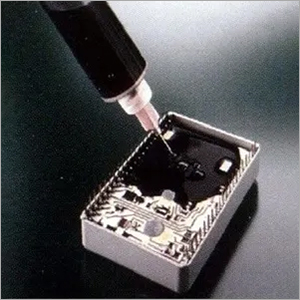

About Peelable Solder Mask

Peelable solder mask is a type of solder mask that can be peeled off the PCB after it is cured. It can be applied in either liquid or film form, and it is usually cured with UV or infrared (IR) light. Unlike non-peelable solder mask, peelable solder mask can be removed without damaging the PCB and can be used for rework and debugging. Peelable solder mask can also help to reduce the risk of shorts due to solder bridging, as it can be peeled off when needed.

Frequently Asked Questions

What is peelable solder mask?

Peelable solder mask is a type of solder mask that is designed to be removed from the board after the soldering process is complete. This type of solder mask can be peeled off of the board, exposing the copper pads and traces, allowing for easier soldering. This type of solder mask is typically used on boards that are going to be reworked, repaired, or inspected.

What is peelable mask for PCB?

Peelable mask for PCB is a type of protective coating that is used to protect sensitive circuitry and components on printed circuit boards (PCBs) during production, assembly and soldering processes. It is designed to be easy to apply and remove, while still providing a reliable barrier against contaminants, corrosive chemicals and mechanical damage. The mask also helps to reduce the risk of electrical shorts and component damage during the soldering process.

What is peel off mask in PCB?

Peel off mask in PCB is a protective coating that is applied over the copper traces and pads after etching to protect them from oxidation. It is a type of solder mask, which is a thin polymer film that is applied to the surface of the PCB to protect it from corrosion and shorts. The peel off mask typically comes in sheets or rolls and is applied to the board with a lamination process. Once the mask has been applied, the excess can be peeled off and removed, leaving the protective layer intact.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SMT Product Category

SMT Red Glue

Price 1500.00 INR / Bottle

Minimum Order Quantity : 1

Attributes : Easy To Operate

Condition : New

Equipment Type : smt product

Warranty : 1 month

SMT Magazine Rack

Price 2800 INR / Piece

Minimum Order Quantity : 1

Attributes : Easy To Operate

Condition : New

Aadi Black SMT Magazine Rack

Price 3800 INR / Piece

Minimum Order Quantity : 1

Attributes : Strong, Durable

Condition : New

Warranty : 1 Year

Send Inquiry

Send Inquiry